How it Works

Chemical EOR Injection

Waterfloods using Polymer, Surfactant and/or Alkali

Polymer addition increases the injectant viscosity and improves sweep efficiency, while alkali and surfactants mobilize oil by reducing the interfacial tension between the oil and water during the flood. Salinity of the water directly correlates to the cost and effectiveness of polymer floods used in the chemical EOR programs.

how it works

Chemical EOR Injection

Waterfloods using Alkali

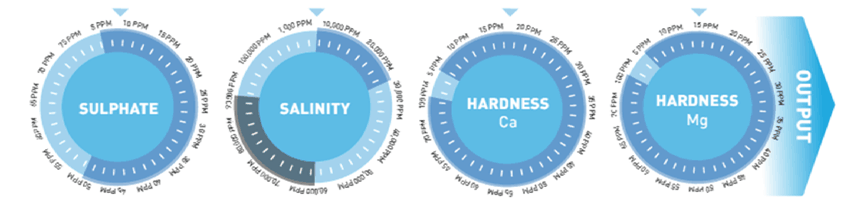

For cEOR processes using alkalinity such as ASP, our H2Ocean Spectrum® cEOR injection packages soften or desalinate the injection water to remove any calcium and magnesium, and/or salinity content to prevent precipitation of these constituents in the reservoir.

how it works

Chemical EOR Injection

Waterfloods using Surfactants

For cEOR processes focused on surfactant flooding, our H2Ocean Spectrum® CEOR injection packages are designed to find the optimum salinity to maximize the surfactant effectiveness.

The Results

Chemical EOR Injection

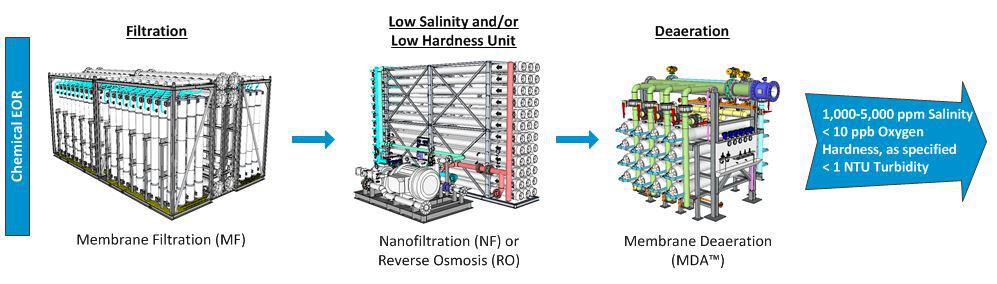

Water Standard’s H2Ocean Spectrum® EOR injection packages reduce chemical costs and consumption by optimizing the injection water properties.

Our in-house expertise works with you to choose the correct filtration, low-salinity and/or low-hardness, and deaeration processes for your project.

Our compact design saves 5-20% space and weight; it can eliminate injector booster pumps, and with our optional MDA Torrnado™ technology, deaeration vacuum pumps can be eliminated.

These key advantages result in an optimal design, lowering CAPEX and OPEX costs over the life of the field and increases OOIP recovery up to 30%.

Our patented H2Ocean Spectrum® control system offers the benefit of switching injection water quality over the life of the field to cater to varying EOR methods.

Chemical EOR Package Layout