Water Standard’s H2Ocean Spectrum® platform provides operators the design flexibility to use our turnkey water treatment technology portfolio or customized solutions using one or a combination of our water treatment technologies for your specific water injection application.

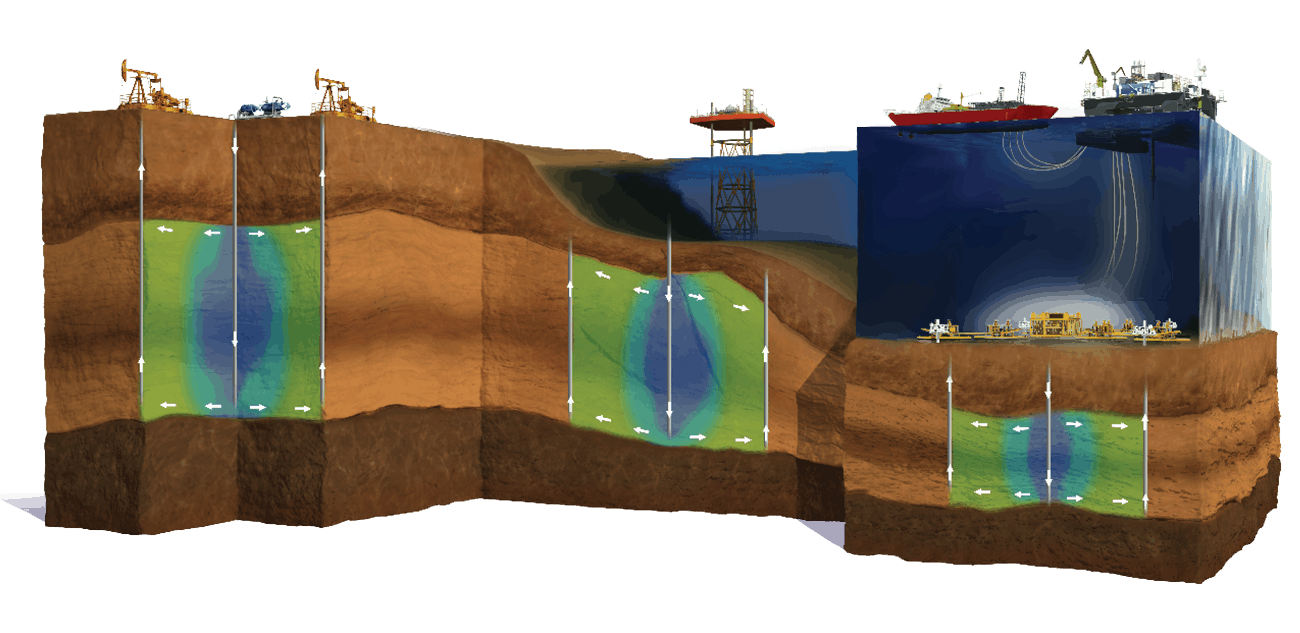

A Water Treatment Platform for Water-Based

Enhanced Oil Recovery (EOR)

Over 50% of the world’s oil recovery operations use waterflooding. Learn how Water Standard’s H2Ocean Spectrum®, for water injection, can help you improve your oil recovery, including our patented control system that can change water chemistry to cater to varying EOR methods over the life of the field.

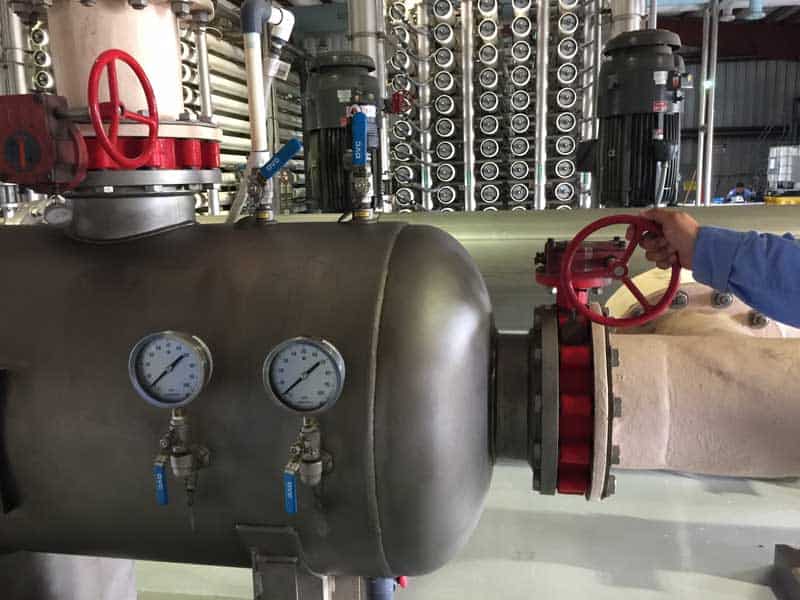

Sulphate Removal

What It Does

Seawater contains up to about 3,600 ppm of sulphate ions. If present during water injection, the sulphate can form scale deposits with reservoir constituents such as barium and strontium. In addition, sulphate plays a major role in reservoir scouring, acting as a nutrient for sulphate-reducing bacteria.

Water Standard’s Sulphate Removal Package (SRP) treats the seawater to remove the sulphate prior to injection to avoid these significant operational challenges.

low salinity injection

What It Does

Low Salinity water injection shifts the properties of a reservoir to a state of water wetness, increasing microscopic sweep efficiency and consequently, increasing oil recovery. Low salinity water also provides sulphate-free water, thereby reducing souring potential and preventing scaling as it increases oil recovery.

Water Standard’s low salinity packages use compact membrane technologies to optimize the design for offshore and onshore applications.

chemical EOR

What It Does

Chemical EOR uses the properties of polymer, surfactant and/or alkali to boost oil recovery. Polymer flooding increases OOIP recovery 10-15% while Alkali, Surfactant, Polymer (ASP) floods have the potential for over 20% additional OOIP recovery.

Water Standard’s H2Ocean Spectrum® customizes the water injection quality (salinity, hardness and sulphate levels) to maximize the efficiency of the chemicals, optimize overall costs and influence oil/water separation after production.