Custom Designed for Water Injection, Industrial, Chemical, Petrochemical & Power Generation

Advanced Water Treatment

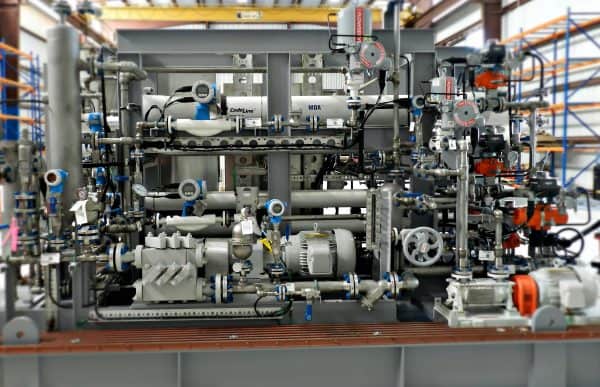

MDA® is a state-of-the-art dissolved oxygen removal system with better oxygen removal, no chemicals, and reduced weight and footprint.

MDA®

Compact Deaeration System

Membrane Deaeration (MDA®) reduces weight and footprint while achieving better oxygen removal to preserve the integrity of your assets.

How it Works

MDA® utilizes hollow fiber membranes to more efficiently remove oxygen from water than traditional vacuum towers.

Benefits

MDA Torrnado™

Ultra-Compact Deaeration System

MDA Torrnado™ utilizes an existing water stream to reduce weight, footprint and costs, including the elimination of vacuum pumps.

How it Works

Same great performance as our standard MDA® while leveraging wasted energy to further reduce footprint, maintenance and cost by removing rotating equipment.

Benefits

A complete portfolio of robust and reliable systems for

effective solids removal.

H2Ocean Spectrum® / H2O Spectrum®

Media Filtration

Conventional solids removal packages for proven results.

How it Works

Media Filtration systems can utilize a variety of media to trap those unwanted contaminants and solids for easy removal.

Benefits

H2O Spectrum®

Coalescing Filters

Achieve lower levels of treated water oil through recovery of colloidal oil.

How it Works

Coalescing filtration polishes oil when conventional oil separation isn’t enough.

Benefits

H2Ocean Spectrum® / H2O Spectrum®

Membrane Filtration

Remove solids from waste water, produced (oily) water, well water, surface water or

seawater.

How it Works

Membrane Filtration, using either microfiltration or ultrafiltration membranes, remove solids from water to protect downstream systems and processes from contamination.

Benefits

A complete portfolio of robust and reliable systems for dissolved salt removal with membranes.

H2Ocean Spectrum®/ H2O Spectrum®

Nanofiltration (NF)

Focused on hardness, sulphate and TOC removal. When you want some pesky salts removed, but not everything.

How it Works

Nanofiltration membranes target specific divalent salts for removal, typically at lower pressures and higher recoveries than conventional reverse osmosis membranes.

Benefits

H2Ocean Spectrum®

Sulphate Removal Package (SRP)

Preserve the integrity of your reservoir and prolong the life of valuable downstream equipment by reducing scaling and souring.

How it Works

Sulphate removal packages utilize nanofiltration membranes that remove sulphates from seawater while allowing other salts to pass through them.

Benefits

H2Ocean Spectrum®/ H2O Spectrum®

Reverse Osmosis (RO)

Target all dissolved solids with brackish water (BWRO) or seawater (SWRO) reverse osmosis systems.

How it Works

Brackish water (BWRO) and seawater (SWRO) systems use the same principal of Reverse Osmosis, harnessing pressure to allow thin-film composite membranes to remove dissolved minerals from the water.

Benefits

Water Standard’s specialized high purity equipment line tackles more demanding applications to meet your project requirements.

H2O Spectrum®

Resin Based Ion Exchange

Target anions, cations or all ions for your high purity water needs.

How it Works

Cation resin trades hydrogen ions for positively charged ions while Anionic resin trades hydroxide ions for negatively charged ions in your water. The hydroxide and hydrogen ions combine to form water when released from the resin.

Benefits

H2O Spectrum®

Electro-Deionization

Regenerable deionization harnessing electricity to reduce costs.

How it Works

Electro-deionization harnesses DC power to draw negatively and positively charged ions in the water toward alternately charged electrodes, typically through a resin or resin sheet.

Benefits

H2O Spectrum®

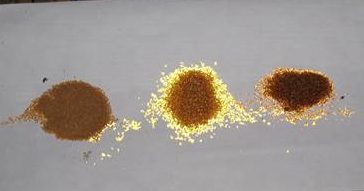

Regenerable TOC Resin

Resin based system specifically targeting total organic carbon (TOC).

How it Works

Dissolved organic removal is achieved using adsorbent polymeric bead media that can be regenerated with steam. During regeneration, the beads are taken offline and adsorbed materials are recovered in a steam stream.

Benefits

Bioreactors use with Reduced Weight, Footprint and Chemical Consumption

H2O Spectrum®

Activated Sludge Processes

Chew through those unwanted contaminants with our biological process expertise.

How it Works

Activated Sludge Processes use a biological colony of bacteria that consumes and digests unwanted contaminants converting them to environmentally friendly molecules.

Benefits

H2O Spectrum®

Membrane Bioreactor (MBR)

Combining membrane filtration and activated sludge processes for effective contaminant removal.

How it Works

This process combines Activated Sludge with Membrane Filtration to chew through those unwanted contaminants, and filter the solids from the water. WS has experience with high

salinity MBR applications typical of produced water treatment.